What is more important: thickness or density of cardboard?

Most companies spend a significant amount of time measuring the density of cardboard during incoming quality control. But this indicator, unfortunately, is not as important as it seems. Why, when placing an order, printers are primarily interested in the thickness of the cardboard, and not the density? Why do they consider this indicator more important and what benefits does the customer receive from it? Let's consider the answers to these questions in our article.

Cardboard is a type of thick paper (the term is taken from Wikipedia). It is a multi-layered material, where the fibers play an important role, creating many layers. The fiber gives the cardboard special properties: density, thickness, plumpness, rigidity, which depend on the production capabilities of the cardboard for running, folding, as well as the ability to keep the shape of the finished product itself.

Cardboard is distinguished by the scope of application:

- packing

- polygraphic

- designer

Packaging cardboard is used for the manufacture of containers and packaging, which determines the main requirements for the material: high rigidity, framework, barrier properties, strength.

The structure of the packaging cardboard includes several layers:

- Lower - produced from high-quality raw materials (bleached cellulose, unbleached cellulose, wood pulp, waste paper);

- The middle is a thick layer, produced from cheap raw materials (waste paper, mechanical pulp, unbleached cellulose, production waste);

- Upper - made from high-quality raw materials;

- Chalked - mostly one or two layers of chalking.

The use of cheaper raw materials in the middle layer allows you to preserve the necessary barrier properties of cardboard, reducing its cost.

Polygraphic cardboard is used for the production of multi-color products that require high-quality printing: folders, brochures, expensive gift packaging, etc. This type of cardboard should not be as rigid as packaging.

Food cardboard is used for the manufacture of disposable tableware: plates, trays, glasses, etc. It is usually chalk, foil and laminated.

The main characteristics of cardboard are: grammage (weight of 1 m2), thickness, moisture. Special technical indicators include: absorption capacity, electrical insulation properties, deformation during wetting and drying, and others.

First of all, let's consider such an important indicator as the density of the cardboard.

Cardboard density refers to the ratio of cardboard weight to sheet area (g/m2). That is, for cardboard with a density of 235 g/m2, it is true that its sheet with an area of 1 square meter weighs 235 g. And for all types of cardboard from all manufacturers, the statement is true that if the cardboard pallet is marked with cardboard with a density of 235 grams, then a sheet of such cardboard with an area of 1 square meter will weigh exactly as much as it should weigh - 235 grams. Under certain conditions, of course. If the cardboard is stored for sure, then it can gain moisture and, of course, it will weigh more.

When ordering products, the customer in 98% of cases specifies the thickness of the cardboard on which the print run should be made. Specifying a certain density, the customer expects to receive a package that will correspond to his ideas, which he received during tactile interaction with a certain material that had exactly this (specified in the application) density. Most often, when people talk about the weight or density of a sheet of cardboard, they mean its thickness.

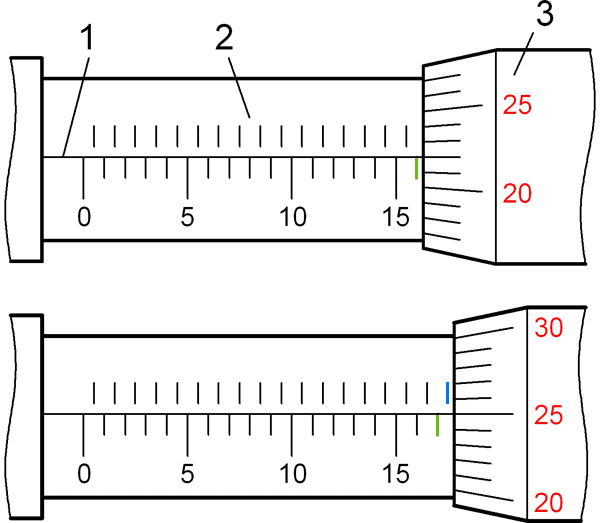

Now consider the concept of cardboard thickness. The thickness is the distance between two surfaces of a sheet of cardboard, measured in thousandths of a millimeter, and the thickness of the cardboard is measured with a special measuring tool called a micrometer. The cardboard used in most cases for cardboard packaging has a thickness of 300 to 800 μm.

Why is it important to specify the thickness of the cardboard when ordering packaging?

The fact is that the thickness of the cardboard and the stiffness of the cardboard of the same density may differ from various manufacturers. The various thicknesses of the base of the paper sheet and the chalk layer, the various composition used for the manufacture of cardboard determines the paper products of various manufacturers.

Let's compare with a real example. We took the specification for the frequently used cardboard in our country and made a comparative table.

| Наіменування картону | SimCote | Аляска Плюс | CartaSolida | SinarVanda | NingboStar | AeglePro | Bohui | AllyKing |

| Виробник, країна | Фінляндія | Індонезія | Китай | Фінляндія | Китай | |||

| Густина картону, г/м² | 235 | 235 | 235 | 230 | 230 | 235 | 230 | 235 |

| Товщина μm | 425 | 425 | 385 | 355 | 250 | 410 | 350 | 385 |

| Густина картону, г/м² | 250 | 255 | 250 | 245 | 250 | 245 | 250 | 250 |

| Товщина μm | 450 | 470 | 415 | 380 | 275 | 430 | 390 | 420 |

| Густина картону, г/м² | 290 | 280 | 285 | 280 | 300 | 290 | 300 | 295 |

| Товщина μm | 550 | 520 | 485 | 450 | 355 | 520 | 453 | 510 |

After carefully studying the comparative table, you can see how strongly the thickness differs with the same density. Thus, with the same density, the thickness can vary up to 100-175 μm, which is a significant indicator for the finished product. And it is important to notice: the deterioration of indicators in terms of thickness does not depend on the country of the cardboard producer. So, we can see from the table that the cardboard of the Chinese manufacturer is not inferior in terms of its characteristics to the Finnish manufacturer. Namely, the thickness of the cardboard makes it possible for the package to look more presentable. But this is not the only reason to give your choice in favor of cardboard thickness. So, if the customer will receive products according to the required thickness of cardboard, then the machine will work without failures and the time for its readjustment will be spent significantly less, which means cost savings.